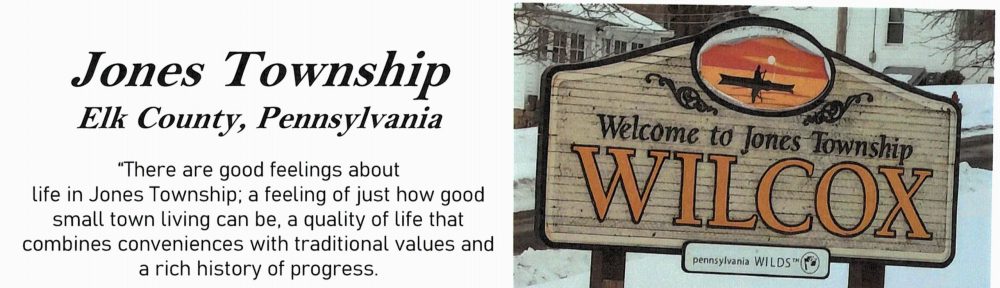

The Wilcox Tannery: Inside View:

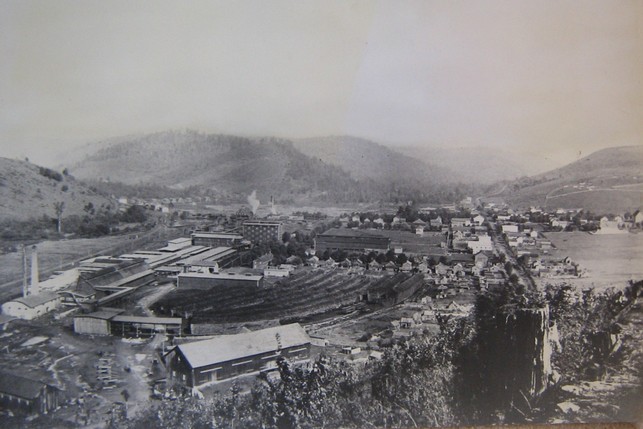

It was 1864 when Theodore Palen and other investors from New York State purchased 10 acres of land from Alonzo Wilcox along the West Branch of the Clarion River. Intending to expand the family’s tanning and leather business, Palen also secured the rights to hemlock bark on another 1500 acres in Jones Township. About 1866 Mr. Jackson Schultz had convinced his brother Maurice M. Schultz to partner and later purchased the Palen family interests in Jones Township.

The Schultz family already had other tannery interests throughout the area and wanted to expand their operations. The site in Wilcox, with the new railroad having just been constructed, offered them the opportunity to expand their business endeavors. In 1867 Maurice M. Schultz came to Wilcox to manage the Wilcox Tanning Company along the West Branch of the Clarion River and the new railroad.

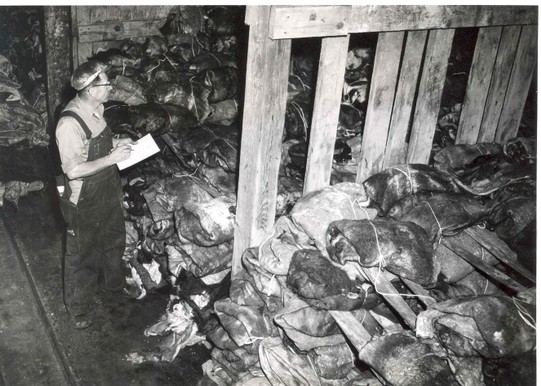

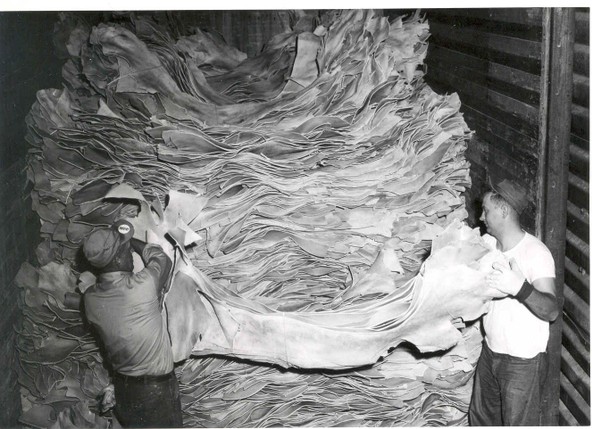

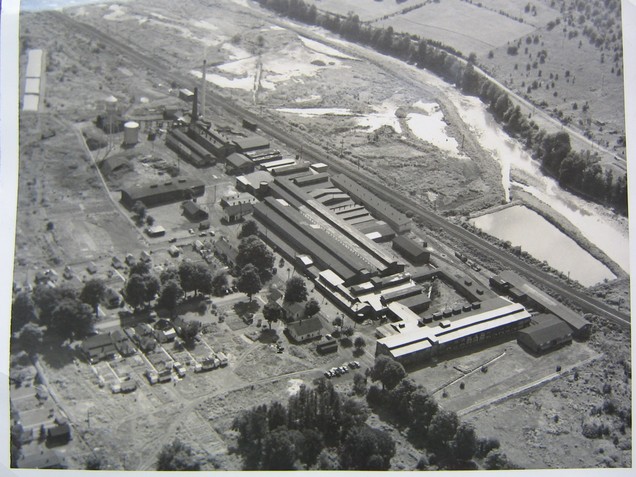

The tannery is said to have, at its peak, employed up to 300 men and additional 400 men to peel bark from the hemlock. As part of the tanning process hemlock bark was required in great quantities. The bark contains valuable chemicals, such as tannin, used to tan the hides. The lumber companies in the region would provide the 25,000 cords of hemlock bark that the tannery required to process the nearly 333,000 buffalo and cow hides processed at the facility annually. The plant had 13 boilers powered by gas wells located at the site. 732 vats, seven (7) feet wide, nine (9) feet long and five and a half (5 1/2) feet deep were encompassed within the facility, making it the largest leather tanning facility in the world.

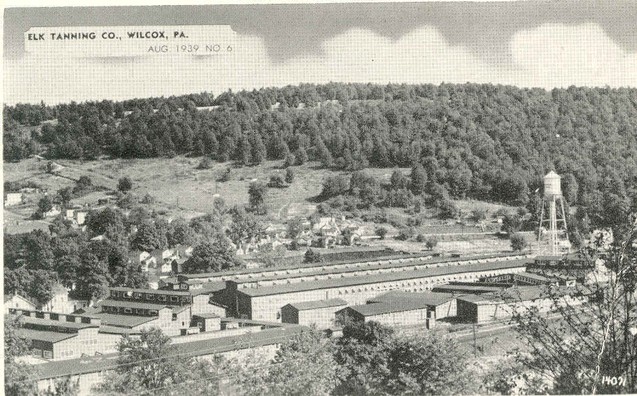

By the start of World War 2, The Wilcox Tannery had liquidated the greater part of it’s property holdings in Jones Township. When the Elk Tanning Company was organized, the Wilcox Tannery was merged into the new company, which operated most all of the still existing tanneries in Elk County. One goal of the new company was to liquidate it’s vast holdings of land that was now stripped of it’s valuable timber and now useless to the company. It also sold off several blocks of buildings and a number of it’s company owned houses in Wilcox.

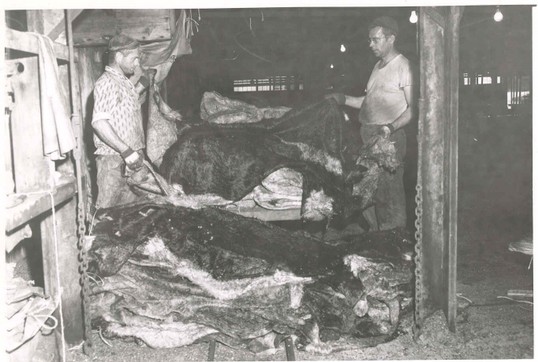

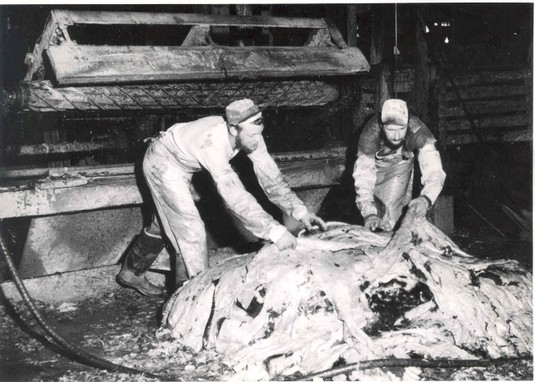

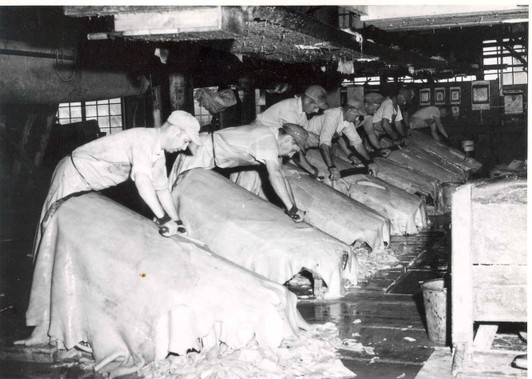

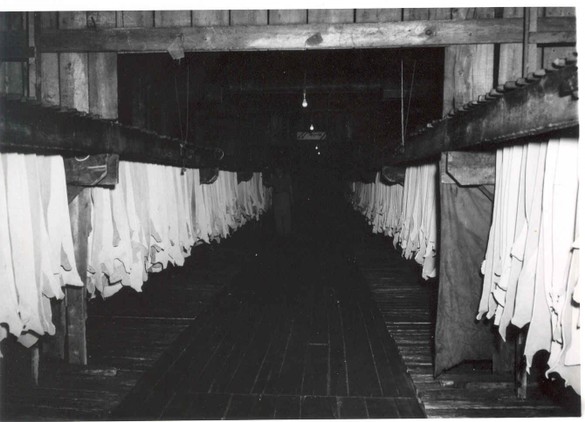

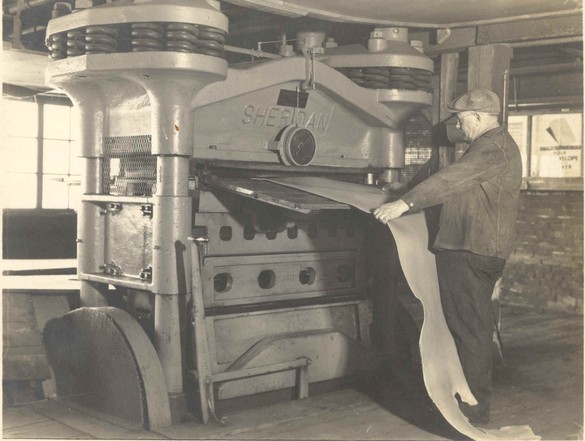

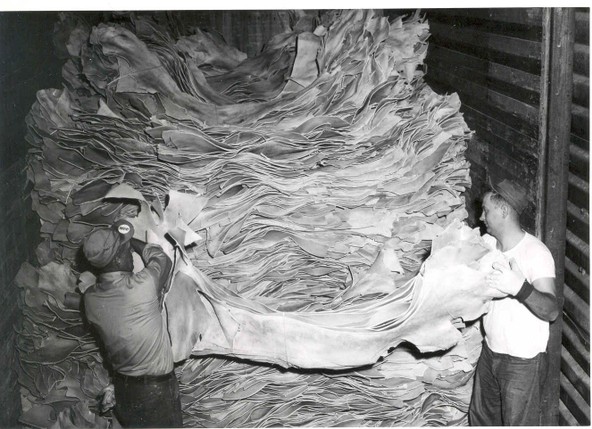

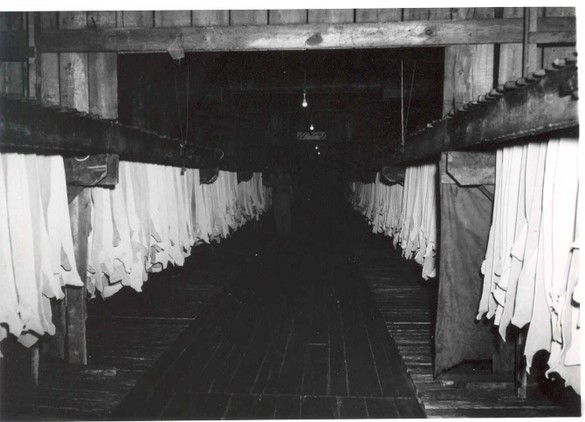

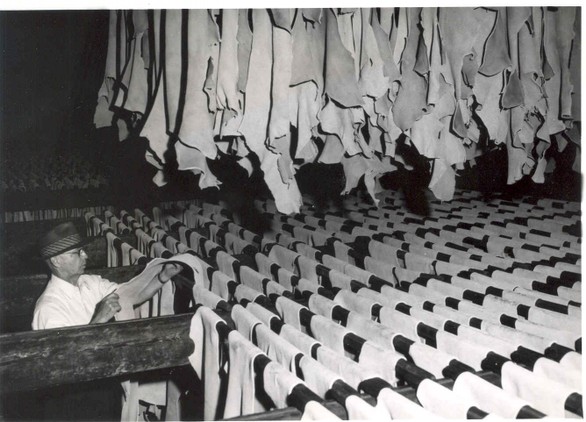

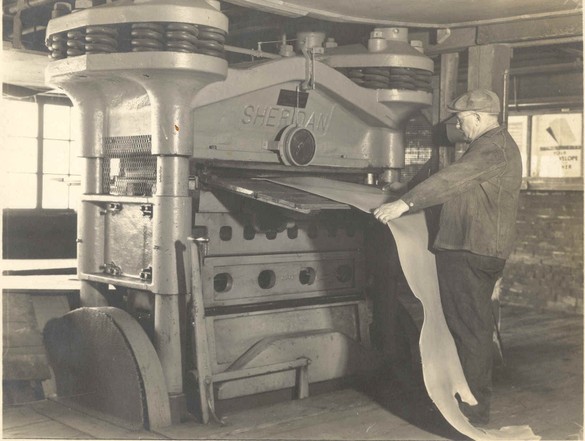

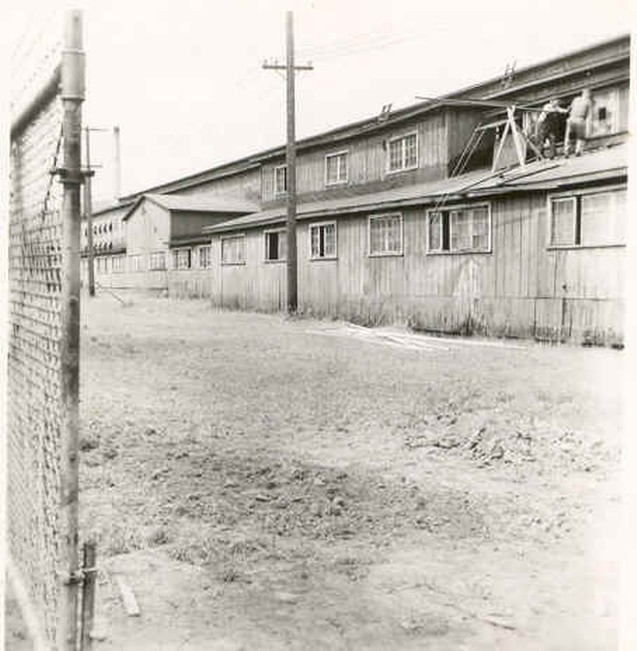

The photos below show what work was like at the tannery.

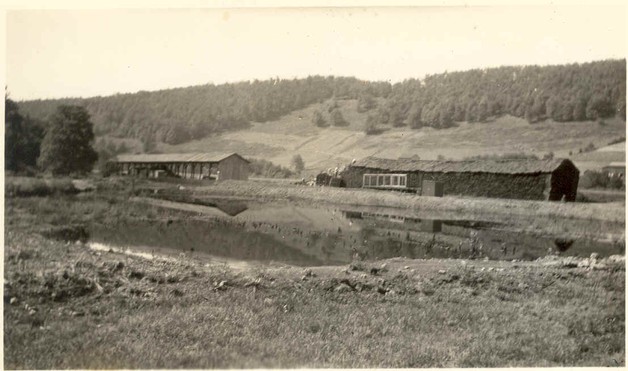

The hides were then moved to vats of tanning liquor for periods of weeks to tan the hides. The vats were about 10 feet square and six feet deep. The Wilcox Tannery had over 732 vats that were in operation.

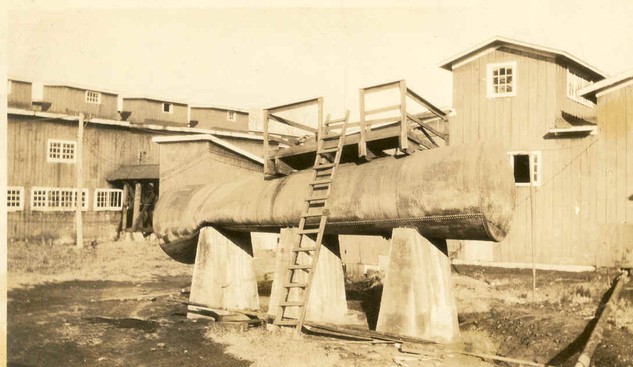

One of the basic elements of the tanning process involved the process of soaking the hides in a solution extracted from finely ground hemlock bark which was boiled into a liquor. This process released various chemicals from the bark (leaching) would then be used to biologically treat the hides, thus providing the durable leather.

This leaching process consisted of mixing the ground bark, sometimes with ground nuts, with water. Steam generators provided heat to the tanks to bring the mixture to boiling which would release the chemicals, called tannins. After the mixture extracted all the available tannin from the hemlock, the somewhat weak mixture was then moved to another tank containing fresh bark. The process was continued with the liquor becoming stronger at each brewing of the mixture.

After the bark chips were leached of all available tannin, the bark was mixed with coal and transferred by conveyor to the boilers to be used as a fuel source.

The strong tanbark liquor was pumped into vats where the hides were immersed for tanning.

After soaking in the vats, the hides were moved to the “Scrub House”. Here the hides were placed into huge drums which were rotated by gas engines. While tumbling in the drums, a mixture of oils and water were added to the hides.

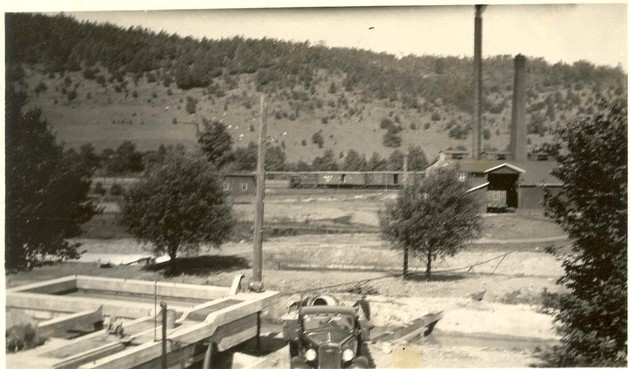

Outside views of the Wilcox Tannery:

Bark from the hemlock trees was transported to the Tannery by rail from a number of sawmills that existed in the area. There were two (2) bark stacking areas, one was next to the to the houses along Oak Street, the other to the south of the Tannery The bark was stacked in curved rows several hundred feet in length.

The bark grinding mill was installed in a building to the east of the furnace building. The building was open at the ends to permit the entrance of box cars. The grinders were located adjacent to the rails allowing the bark to be thrown directly into the grinder.

From the grinder, the bark would be moved by forced air to the leach house to be mixed into the tannin liquor.

The Tannery Fire of 1966

On July 27, 1966, massive flames billowed hundreds of feet skyward as fire leveled a quarter-million feet of framed industrial buildings at the former Wilcox Tannery in Wilcox. The fire sirens sounded at 12:30 this Wednesday morning. For a time, the inferno lifted tarpaper and other materials in to the air over a wide area, destroying a large nearby dwelling.

There were no reports of any injuries. Firefighter from eight local communities fought to keep the blaze from destroying the entire town which was only a few hundred feet from the burning structure, Firefighters from Kane sent two units, St. Marys with two, with Johnsonburg sending four units. Firefighters fro Emporium, Port Allegany, Smethport, and Mt. Jewett assisted the Wilcox Department led by Chief C. P. Dietrick.

While hose lines were strung like spaghetti to the Clarion River to fight the fire, firefighters pumped close to 70,000 gallons of water from the Wilcox reservoir. As the fire spread throughout the maze of industrial buildings, flames burnt the main electric power distribution lines supplying electricity to the Wilcox and Rasselas area. West Penn Power rushed in emergency repair crews to restore power.

Residents watched in horror as the searing heat began to blister the siding on homes as far away as 200 feet from the fire. The homes of Mr. & Mrs. James Steve was gutted by the fire. The homes of three other families, Walter Polinski, Clarence Fiscus, George Mehalko, and James Turzanski were severely damaged.

The old, dry, wooden, buildings produced a spectacular fire that was seen for miles. State Police Sgt. John Dussia reported that the fire was first reported and appeared to be in an industrial area southeast of Kane and investigated. He continued on eight miles to discover the fire in Wilcox.

Firemen at the scene indicated that the blaze is believed to have been started by an arsonist. Several local barns and other rural building have been intentionally set on fire recently in the area. No one was ever charged with the crime. The Tannery buildings were under the ownership by the Kovalchik Salvage Company of Sykesville. The company was in the process of salvaging some of the buildings while demolishing others. Machinery and other valuable equipment had long since been removed from the buildings.

The day after the blaze, crews from West Penn Power were on scene to restore power to the community. The valley of Wilcox was partially darkened as smoke hung heavy over the town for miles. Since it was a calm day the smoke lingered over the former industrial giant like a cloud, State Police rerouted traffic traveling on Route 219.

Today only the remains of the foundation for the plants sewage treatment process are visible. The modern State Route 321 cuts directly through the former site. The site was later turned over to the Wilcox Area Development Corp. which has since sold off industrial building lots. These lots are now occupied by Precision Compacted Components, Cameron Diversified Products, Elcam Tool & Die. The Thorco Bottling Company once operated at the site and constructed the building now occupied by Cameron Diversified Products, Elcam Tool & Die.

Although these new industries provide valuable jobs and economic benefits to the community, they will never replace the great wealth provided to the town as did the Wilcox Tannery.